– Based on a Tony Holmshaw (TH) clutch

- Remove from crank and place on bench

- Undo bolts on face of clutch one turn on each bolt doing every other bolt.

- Collect washers from top of pillars

- Collect washers from pressure plate on top of the springs (if fitted)

- Clean gunge from behind centre thrust bearing

- Clean gunge out of centre plate recess

- Remove spider

- Remove All Plates

- Deep clean all parts

Removal of pins

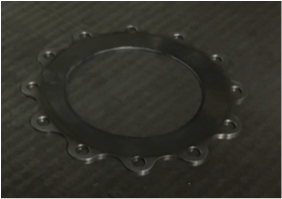

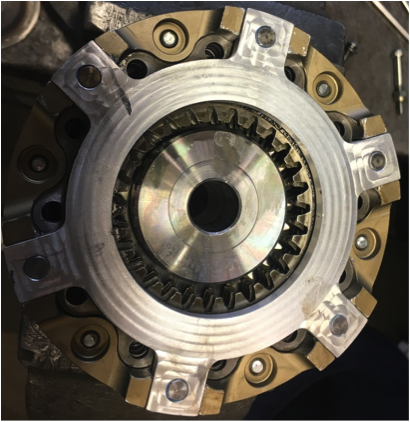

- If replacing spider due to excessive wear as seen in photo below.

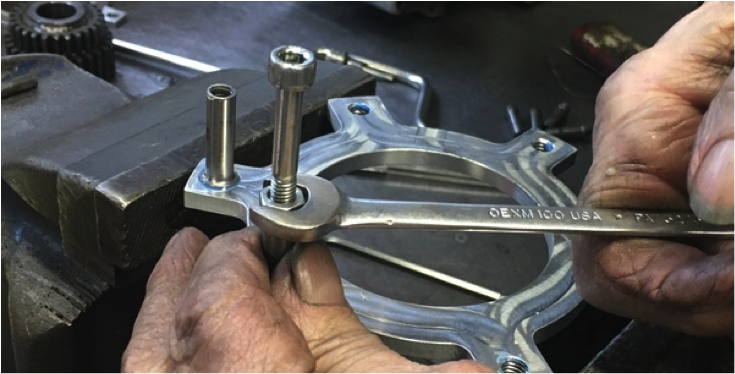

- Screw in 6mm bolt down pillar 15mm nip in vice turn spider to undo do not put pillar in vice without as the pillar will collapse.

Check fibre and steel plates

- For flatness/ dishing on a flat surface, if warped or dished replace make sure you check new ones

- Fibre plates to be between 0.115” – 0.125” (measure all plates in two to three places)

Standard clutches final steel plate must sit flush with top of drum, if above repack so lower if not steel plate will rotate and hold clutch open.

- Pack thickness in a Holmshaw clutch not such an issue as no edge to fall over.

- Clean pillars of old Loctite

- Replace all damaged cap head 6mm bolts, this is common, and clean reused

Build from scratch using new spider (if using old spider and pillars skip 1st part)

- Put spot of Loctite on the six pillar threads in spider

- Screw 6mm bolt with locknut 15mm in to pillar, then tighten pillar down on spider with the nut with a firm tug.

- Remove 6mm tightening bolt holding the pillar so it does not move.

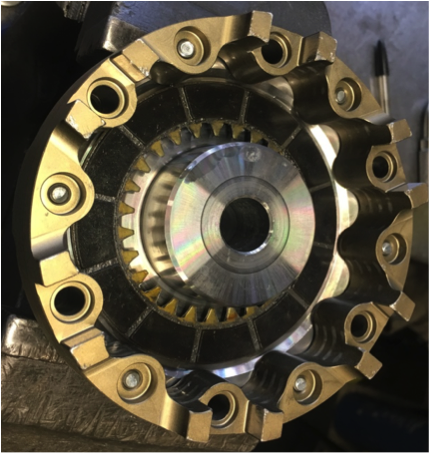

- Build plate pack in clutch ring around clutch center

- Light gear oil on each plate both fiber and steel

- Fibre plate 1st then steel (total of 5 fibre 4 steel)

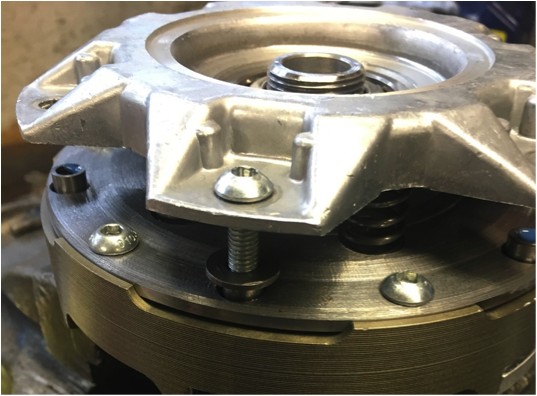

- Fit spider so dropped in the back

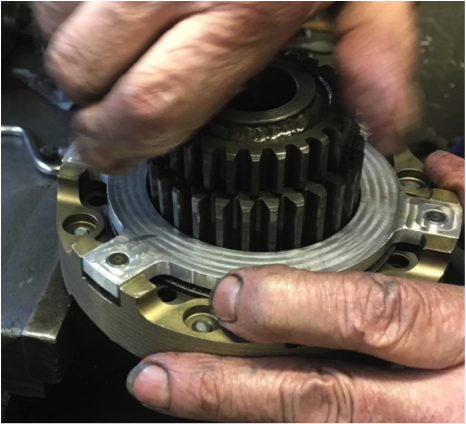

- Line up fibre plates by inserting primary drive gear twisting / turning till all plates aligned

- Hold assembly together including primary gear and turn over and place in vice to support spider and stop plates dropping out.

- Place in recess on front plate

- Loctite pillar threads

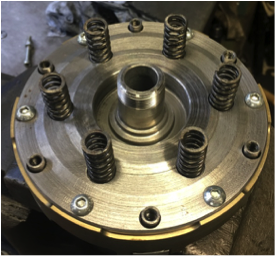

- Place washers in pressure plate spot of oil in each hole to stop them falling out

- Place pressure plate on springs

- Loctite 6mm bolts

- Put in washer above pillar below pressure plate

- Put in all six bolts loosely

- Tighten evenly 1 then 4, 2 then 5 , 3 then 6

- 1 breath tight using non balled Allen key.

- When built correctly the primary gear will lift in and out easily.