- As with crank split Heat and remove from the left case

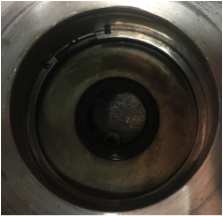

- Remove main bearing oil seals replace every rebuild

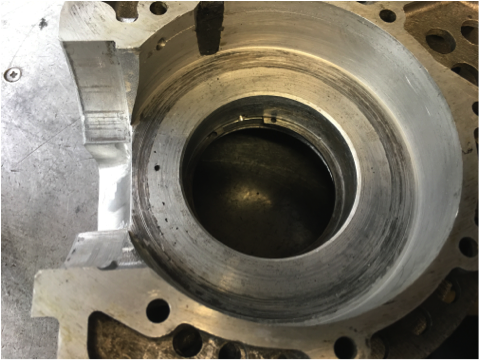

- Remove main bearing oil splash shield by removing circlips on out side of case and tap out replace if warn or cracked

- Clean crank cases Inside and out

Removal of main bearings

- Using Knife edge bearing puller To remove main bearings from crank

- Finsh removal with tire leavers

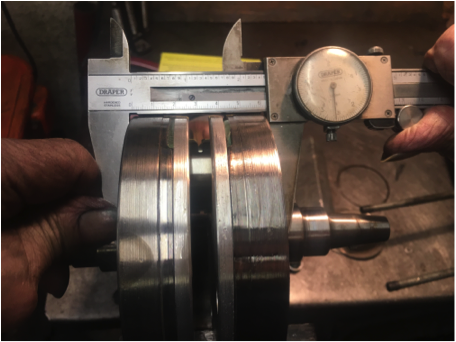

- Crank assembled width 62.5mm

- Main crank bearing (big end] replace prox 2-3 seasons Yamaha every 3 seasons

- Crank rebuild get someone competent to do it .

Engine rebuild

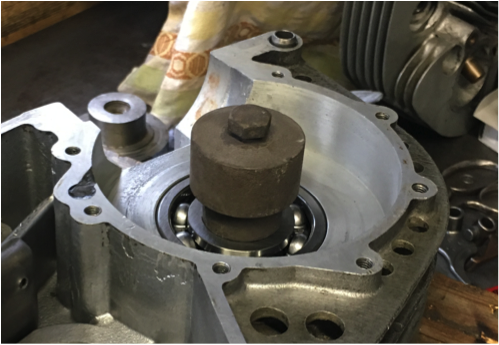

Main Bearing Re-fit

Lay crank case flat

Circlips either side of oil way

Lay in wash Plates, Nipple on plate between circlip gap

Heat Up Crank Cases until main bearings drop in.

Weigh down on top of main bearing to hold in place while cooling

Repeat on opposite crankcase.

Fitting Crank shaft in left side case

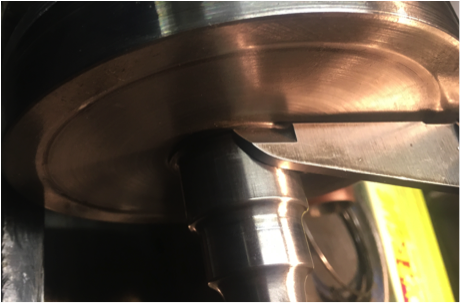

Using custom made mandrel that fist loosely (8-10 Thou or 0.2-0.3mm“ Slack when cold)

Heat up mandrel, place in crank bearing to heat the inner of crank bearing to expand to make crank fitting easy with no force

Once hot insert crank do not use excessive force.

Gearbox

Re assembly same as Haynes manual Except 3/5th Gear mods

Pages from Haynes manual (pdf)

Important the gear cluster is inserted as a cluster.

Tap down into place

Check operation by turning gears and selector drum.

Gear Change Shaft

Check all engaging surfaces for excessive wear and double up Spring (2 springs where the pen points)

Check Gear change return spring for cracks and good tension, Must be tough.

Fitting right hand case

Smear “stay well seal” (none setting jointing compound) sealant round crankcase and gearbox faces. Paint on with small brush for V thin layer.

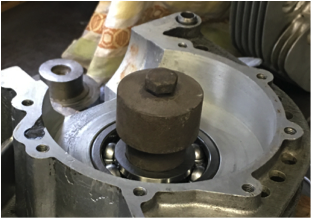

In right hand crank case, Heat up mandrel, place in crank bearing to heat the inner of crank bearing to expand to make crank fitting easy with no force.

Once center of bearing hot Lay on top of left crank case and tap gently into place.

Bolt up the two crankcases tighten every other bolt round and round the case to 9.5 lbf ft – 12.9N.m

****** Before progressing make sure crank spins freely *****