- Set up on 4” block as photo

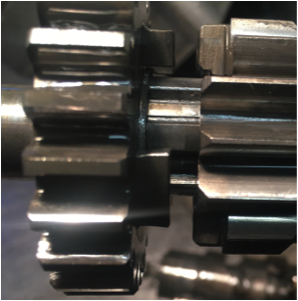

- Put into 3rd gear to check dog penetration it should be flush with penetrated gear (1st)

- Remove Neutral Holder Ball and spring (from the underside of the engine)

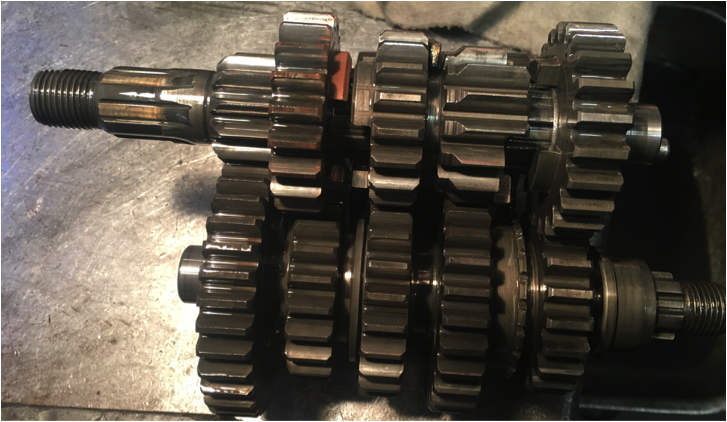

- Tap Out gearbox shafts evenly to remove as a single unit

- Check dogs for rounded corners and bits missing of face

- Clean and inspect Selector drum

- Clean and inspect fork shaft Roll on machine table to check for bend any more than 1 thou is to much

- Check selector forks for wear, photos show different stage of wear

- Output shaft on roller bearing???

- Check all bearings in cases for cracks flat spots rough to turn replace as required